Industry news

Only with sufficient know-how and facilities can foundries face the increasing popularity of structural die casting in the automotive sector.

( Source: Pixabay / CC0 )

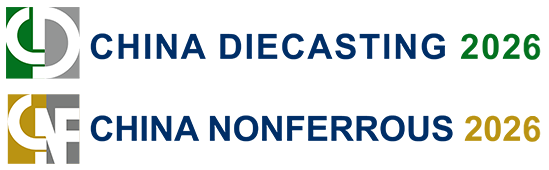

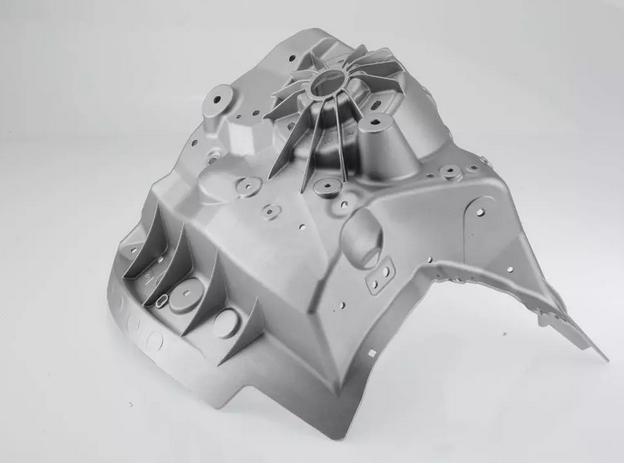

In car manufacturing, an increasing number of structural components such as shock towers (Image 1) are being implemented. They can be used to replace multiple individual components, thereby substantially lowering the weight of the car. Lightweight construction is significant for hybrid and new electric vehicles coming to market: the additional weight of batteries and the electric motor for hybrids can be substantially offset by replacing steel structures with aluminum die castings. The market for structural components has already multiplied over the past five years. At the same time, manufacturing costs were decreased by approximately 20 %; however, OEMs suggest that an additional 20 to 30 % cost reduction is required to make these parts viable for high volume vehicles (Image 2).

Potential for Reducing Costs

Within the entire process chain, there are various parameters that could reduce costs. For example, the wall thickness of components could be reduced, secondary alloys could be developed, and the expenses incurred with heat treatments could be reduced.Encouraging results were achieved with reducing wall thickness. For some components, wall thickness has already been reduced by 20 % – while adhering to all mechanical requirements. "Approximately 40 % of the costs of components are for materials. Our estimate shows that approximately 10 % of the total costs could be saved if thinner walls could be consistently achieved" explains Hermann Roos, Structural Process Manager for Bühler Die Casting. "However, reduced wall thickness brings new challenges for die casting as well as for die production and downstream processes. For example, process fluctuations have an even greater effect on the quality of components. Thinner wall structural parts require close cooperation between the car manufacturer and the foundries with extensive know-how.

The recent development work of the alloy manufacturers shows encouraging performance of secondary aluminum used for structural components. "We anticipate that secondary alloys will be used in the coming years for automotive body parts", says Hermann Roos. He continued by stating: "A substantial advantage, beyond the positive environmental impact – is the lower overall material price".

Costs can also be lowered if the heat treatment is simplified and/or eliminated. "New alloys offer impressive mechanical properties without heat treatment." added Hermann Roos. "However, these alloys are still being validated by the automotive industry".

Knowledge Leads to Greater Success

As the die casting industry continues to develop, three criteria are the focus: short cycle times, high uptime and reliable part quality. More information about this is provided by the Overall Equipment Effectiveness (OEE). Optimizing the OEE of the die casting cell requires in-depth process knowledge. This expertise helps engineers quickly find the proper parameters to adjust in order to reach higher output. This is particularly true when casting challenging components like structural parts. "Of course high performance facilities are required, but above all, customers need the know-how we are happy to share with them", states Hermann Roos. "Beyond that, we have a comprehensive portfolio of products and services throughout the entire manufacturing process" .

Defining and selecting the most suitable production process is a crucial step: depending on the components to be manufactured, that is why we work together with the customer to determine not only the suitable die casting machine and the required peripheral devices, but also to determine the corresponding parameters to ensure optimal production levels. "We also support die casters by providing professional services such as die design, die cooling and filling simulations", added Hermann Roos. Bühler offers an extensive range of courses at Bühler’s technology center or at the customer’s facility. In summary, Hermann Roos states: "I think that is also what our customers value: in addition to maintenance and service, we work with them towards process optimization over the long term".

Cooperating for the Structural Process

For further developing structural components especially as they are applied to high volume product lines, cooperation across the industry is essential. This begins with the development of the BIW (Body in white) at automotive manufacturers. "It is conceivable, for example, to provide designers additional training in designing components for casting", says Hermann Roos pointing out an option for how structural components could soon become distributed more widely in motor vehicles. But the rest of the industry is also called to work on making the die casting process more attractive, thus improving its competitive position versus other processes.

Article Source: SPOTLIGHTMETAL